|

|

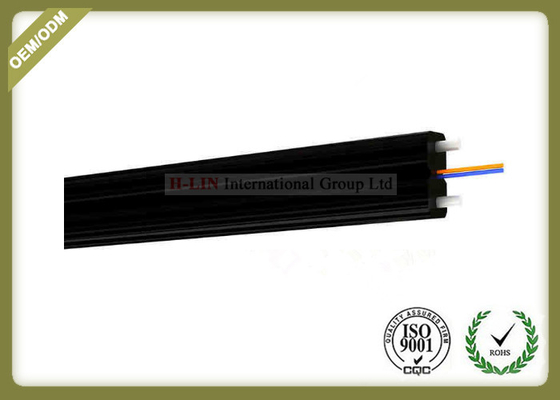

2core FTTH Fiber Optic Cable FRP Strength Member black color with SC Connector

Product Details:

Payment & Shipping Terms:

|

| Core Number: | 2 | Jacket: | LSZH |

|---|---|---|---|

| Fiber: | G657A | Diameter: | 2.0*3.0mm |

| Sheath Color: | White/black | Application: | Telecommunication Network |

| Strength Member: | FRP/KFRP/Steel Wire | Loose Tube Material:: | PBT |

| Highlight: | fiber drop cable,fiber optic drop cable |

||

Fiber Optic FTTH Drop Cable for making Patch cord with SC connector

Product Description

The structure of butterfly fiber cable (leather wire cable) is to integrate small bending radius single mode fiber and two symmetrical reinforcement in flame retardant sheath. The strength member can be steel wire, KFRP or GFRP, and the sheath material can be flame retardant PVC or low smoke halogen free fuel , and the sheath color can be white, black or user. Other colors to be asked. The sheath structure which is easy to tear and the allowable bending radius makes the installation of optical cable convenient. The fiber optic cable can use G.657 fiber, the fiber has excellent bending performance, small bending radius can be less than 15mm, especially suitable for indoor cabling with small turning radius, such as wall corner, indoor panel.

Optical fiber:

We adopt the best Yangtze G657A flexural optical fiber at present. The loss meet the requirements of the national standard. The bending radius is only 7.5mm, the bending loss is small, and the bending life is long.(The G652 fiber used by online merchants is not suitable for FTTH for dry optical fiber) The cost of flexural optical fiber is about double of ordinary optical fiber. Yangtze, beacon fire, Tong Ding and other major brands also use G657A2 optical fibe

Sheath:

the new high environmental PVC rubber particles. Cold resistant, heat-resistant and corrosion resistant. The luster is strong, beautiful and practical.

Steel wire:

the real use of reinforced phosphating steel wire. Surface phosphating treatment, antirust, corrosion resistance, tensile strength can reach 2500mpa, some manufacturers of copper clad iron strength is only about 700MPa, far below the national standard.

Each reel of cable passed the OTDR test before shipping

This product adopts anti bending G657-A2 core, and the loss reaches the standard. The bending radius is up to 7.5mm, and the bending life is longer. More suitable for indoor / outdoor complex wiring environment! The bending loss is much less than that of other cores, and is perfectly compatible.

Characteristics

Special low-bend-sensitivity fiber provides high bandwidth and excellent communication transmission property;

Two parallel FRP strength members ensure good performance of crush resistance to protect the fiber;

Simple structure, light weight and high practicability

Novel flute design, easily strip and splice, simplify the installation and maintenance;

Low smokeand flame retardant sheath.

Fiber Parameters

| No. | Items | Unit | Specification | ||

| G.657A1 | |||||

| 1 | Mode Field Diameter | 1310nm | μm | 9.0±0.4 | |

| 1550nm | μm | 10.1±0.5 | |||

| 2 | Cladding Diameter | μm | 124.8±0.7 | ||

| 3 | Cladding Non-Circularity | % | ≤0.7 | ||

| 4 | Core-Cladding Concentricity Error | μm | ≤0.5 | ||

| 5 | Coating Diameter | μm | 245±5 | ||

| 6 | Coating Non-Circularity | % | ≤6.0 | ||

| 7 | Cladding-Coating Concentricity Error | μm | ≤12.0 | ||

| 8 | Cable Cutoff Wavelength | nm | λcc≤1260 | ||

| 9 | Attenuation(max.) | 1310nm | dB/km | ≤0.4 | |

| 1550nm | dB/km | ≤0.3 | |||

| 10 | Macro-Bending Loss | 1turn×10mm radius @1550nm | dB | ≤0.75 | |

| 1turn×10mm radius @1625nm | dB | ≤1.5 | |||

Cable Parameters

| Items | Specifications | |

| Fiber Counts | 2 | |

| Colored Coating Fiber | Dimension | 250±15μm |

| Color | Blue,Orange | |

| Strength Member | Dimension | 0.4mm |

| Material | Steel | |

| Self-Supporting Member | Dimension | 1.0mm |

| Material | Steel | |

| Jacket | Dimension | 5.2±0.2mm×2.1±0.1mm |

| Material | LSZH | |

| Color | Black | |

Mechanical and Environmental Characteristics

| Items | Unit | Specifications |

| Tension(Long Term) | N | 300 |

| Tension(Short Term) | N | 600 |

| Crush(Long Term) | N/10cm | 1000 |

| Crush(Short Term) | N/10cm | 2200 |

| Min. Bend Radius(Dynamic) | mm | 20D |

| Min. Bend Radius(Static) | mm | 10D |

| Installation Temperature | ℃ | -20~+60 |

| Operating Temperature | ℃ | -40~+70 |

| Storage Temperature | ℃ |

-40~+70 |

Comparasion of strength member material:

If the strength member are made by copper clad iron,after a period of time in air, it is easy to oxidize, broken and has poor tensile strength.

But we use the strengthened steel wire ,it is treated by phosphating, and is resistant to embroidery and corrosion resistance. The strength is 5 times that of copper coated iron.

![]()

![]()

Made to patchcord.

![]()

-

Fiber Optic FTTH Aerial Drop Cable 1 Core Three Steel Wires Special For Outside Use

-

Outdoor Fiber Optic Drop Cable 1 Core Steel Wire PVC / LSZH Jacket Flexible

-

Indoor 4 Core FTTH Fiber Optic Cable Black LSZH Jacket CE/ISO/ROHS Certificated

-

2 Cores Outdoor FTTH Fiber Optic Cable Single Mode With FRP Strength Member LSZH Jacket

-

One Core FTTH Drop Cable High Practicability For No Weak Current Space

-

Light Weight FTTH Aerial Drop Cable Novel Flute With Non - Metal Strength Member