|

|

12 Core Outdoor Fiber Optic Cable All - Dielectric Self - Supporting With Non - Metallic FPR

Product Details:

Payment & Shipping Terms:

|

| Numbers Of Core: | 12 | Fiber Type: | SM/MM |

|---|---|---|---|

| Strength Member: | FRP(non-metallic ) | Material Of Jacket: | PE Or AT |

| Strength Member: | Kevlar Yarn | Temperature Range: | -40℃- +70 ℃ |

| Life Span: | 30 Years | Largest Span: | Largest Span Is Over 1000m |

| Highlight: | waterproof fiber optic cable,outdoor armored fiber optic cable |

||

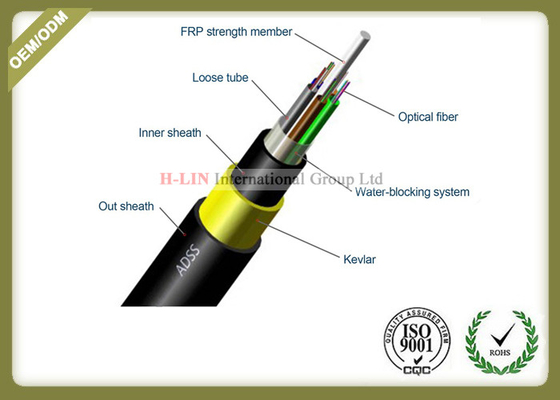

All-dielectric Self-supporting(ADSS) 12 Core SM Double Sheath Aerial Optical Fiber Cable with non-metallic FPR

12core ADSS Cable

Description

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

- FRP, Fiber Reinforced Plastic, as central strength member

- Fibers are positioned in the PBT loose tube filling with water-blocking gel;

- Aramid yarn is used as tensile components to meet the requirements of high tensile strength and performances of stress and strain. The control of aramid application is designed according to the ADSS mechanical requirement.

- The inner jacket adopts PE material; the out jacket adopts PE for electric potential less than 12KV and AT (anti-tracking) for electric potential more than 12KV

Features

Can be installed without shutting offthe power.

ExcellentAT performance. The maximum inductive at the operating point ofAT jacket can reach 25kV.

Light weight and small diameter reducing the load caused by ice and wind and the load on towers and backprops.

Large span lengths and the largest span is over 1000m.

Good performance oftensile strength and temperature.

The design life span is over 30 years.

Form one single mode fiber

| Item | Unit | Specification |

| Attenuation | dB/km | 1310nm≤0.4 |

| 1550nm≤0.3 | ||

| Dispersion | Ps/nm.km | 1285~1330nm≤3.5 |

| 1550nm≤18.0 | ||

| Zero dispersion wavelength | Nm | 1300~1324 |

| Zero dispersion slope | Ps/nm.km | ≤0.095 |

| Fiber cutoff wavelength | Nm | ≤1260 |

| Mode field diameter | Um | 9.2±0.5 |

| Mode field concentricity | Um | <=0.8 |

| Cladding diameter | um | 125±1.0 |

| Cladding non-circularity | % | ≤1.0 |

| Coating/cladding concentricity error | Um | ≤12.5 |

| Coating diameter | um | 245±10 |

| bending,dependence induced | 1550nm, 1turns,32mm diameter | ≤0.5 db |

| attenuation | 100rums,60mm diameter | |

| Proof test | kpsi | ≥100 |

Each Requirement

- – UV colored fiber

- – Loose tube with 2- 12 core inside Φ2.10 ±0.15 ㎜

- – Central strength member FRP

- – Water barrier tape

- – Inner jacket: PE

- – Aramid yarn

- – Out jacket: PE

| Suitable span (m) (NESC standard) | A | 160 | 230 | 300 | 370 | 420 | 480 | 570 | 670 | 750 | 800 | 880 | 1000 | 1100 | 1180 | |

| B | 100 | 150 | 200 | 250 | 280 | 320 | 380 | 460 | 530 | 560 | 650 | 750 | 800 | 880 | ||

| C | 140 | 200 | 290 | 350 | 400 | 460 | 550 | 650 | 750 | 800 | 880 | 1000 | 1100 | 1180 | ||

| D | 100 | 150 | 200 | 250 | 280 | 320 | 380 | 460 | 510 | 560 | 650 | 760 | 830 | 900 | ||

| Cable OD | mm | 12.5 | 13 | 13.3 | 13.6 | 13.8 | 14.5 | 14.9 | 15.1 | 15.5 | 15.7 | 16.3 | 16.8 | 17.2 | 18 | |

| Nominal weight | PE Outer Sheath |

kg/km | 125 | 132 | 137 | 145 | 147 | 164 | 171 | 179 | 190 | 195 | 211 | 226 | 236 | 250 |

| AT Outer Sheath |

136 | 142 | 148 | 156 | 159 | 177 | 185 | 193 | 204 | 210 | 226 | 242 | 253 | 268 | ||

| Max. Tensile Strength |

kN | 4 | 6 | 8 | 10 | 12 | 15 | 18 | 22 | 26 | 28 | 34 | 41 | 45 | 50 | |

| Daily Tensile Strength |

kN | 1.5 | 2.25 | 3 | 3.6 | 4.5 | 5.4 | 6.75 | 7.95 | 9 | 10.5 | 12.75 | 15.45 | 16.2 | 18 | |

| Modulus of elasticity | kN/mm2 | 7.6 | 8.3 | 9.45 | 10.8 | 11.8 | 13.6 | 16.4 | 18 | 19.1 | 19.6 | 20.1 | 24 | 25.1 |

26.1

|

|

PE outer sheath is a good choice for 10KV and 35KV electric lines; 110KV and 220KV electric lines must adopt AT outer sheath

Temperature range

Storage or transportation: -40~70℃ Operation: -40~70 ℃

Application

The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines under 110kV, PE outer sheath is applied. FOR power lines equal to or over 110kV, AT outer sheath is applied. The dedicate design of aramid quantity and stranding process can satisfy the demand on various spans.

![]()

![]()

-

Central loose tube cable,MM OM4,water blocking glass yarn,6.0mm for outdoor/indoor use

-

Outdoor Fiber Optic Cable GYTA Aluminum Polyethylene Laminate

-

GYFTY outdoor fiber optical cable with FRP strength member with armid yarn for

-

Loose tube stranding GYFTY outdoor fiber optic cable with FRP with armid yarn

-

CPRI LC to LC FTTA outdoor fiber optic patch cord duplex 7mm diameter for outdoor use

-

Underground Armored Outdoor Direct Buried Fiber Optic Cable GYTA53 reach to 288cores