|

|

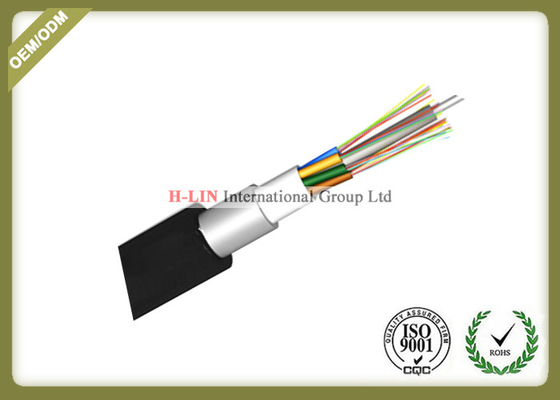

Outdoor Stranded Loose Tube Fiber Optic Cable With Aluminum Polyethylene Laminate

Product Details:

Payment & Shipping Terms:

|

| Fiber Type: | Aluminum Armored Cable | Central Strength Member: | Phosphatized Steel Wire |

|---|---|---|---|

| Jacket: | PE | Outer Diameter: | 10.5~18.8+_0.5mm |

| Fiber Count: | 2~288core | Temperature Range: | -40degree +70 Degeree |

| Weight: | 103~302kg | Aplication: | Outdoor Communications,Long Distance And Local Area Network(LAN),Communications. |

| Structure: | APL Moisture Barrier | ||

| Highlight: | waterproof fiber optic cable,outdoor armored fiber optic cable |

||

Stranded Loose Tube Cable With Aluminum Polyethylene Laminate (LAP) for outdoor use (GYTA)

Company Profile:

H-Lin is the trademark of H-Lin International Group Limited

It is a Hi-Tech enterprise specialized in manufacturing and exporting optical communications equipments and network accessories.

It has more than 10 years experience in optical and telecom communication field.

At present the products including fiber optic assembly,optic distribution frame,optic media converter,SFP Module,CAT5E-7 cable,optical fiber cable etc.

The main markets focus on Mid East, North America and Southeast Asia.

It is well-thought-of in old clients by quick response and good service. Keeping faith and empressement will be always in all staff's mind.

Description:

Outdoor direct buried fiber cable is a kind of transmission cable which is especially designed to be buried under the ground without any extra covering or piping to protect it.There is steel wires or steel tape at the protection layer of the cable.It can directly buried at the ground,with the function of bearing physical damage and preventing soil corrosion.It can be applied to WAN/LAN telecommunication and harsh environmental conditions such as steep hills, rivers, etc.

The fibers, 250μm,are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core, which is filled with the filling compound to protect it from water ingress. Then, the cable is completed with a PE sheath.

Important notice:

Many domestic small factories use inferior or waste optical fibers to imitate A-grade optical fibers, non-woven fabrics as water-blocking tapes, waste electric-wires and rubber slippers smashed as raw materials for the outer sheath of cable. Those inferior cables will cause many problems such as short transmission distance, low bandwidth, intermittent signal and easy-to-crack and water seepage of the cable jacket, etc. For the recent years, there are many cases that many overseas customers who bought such inferior cables from China were frustrated to find that the cables can not be used after constructing. It’s not workable to return them to China as the Chinese government will levy high import duties on optical fiber cables. The customers cannot claim for any compensation and suffered huge losses.

Characteristics.

Good mechanical and temperature performance

· High strength looes tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· Specially designed compact structure is good at preventing loose tubes from shrinking

· PE sheath protects cable from ultraviolet radiation

· The following measures are taken to ensure the cable watertight:

. Steel wire used as the central strength member

. Loose tube filling compound

. 100% cable core filling

. APL moisture barrier

Standards

GYTA cable complies with Standard YD/T 901-2001as well as IEC 60794-1.

Packing:

Label will be sticked at wooden drum,include style of optical cable and fiber account,length,Gross weight KGS,Total drums amount,manufacture date

![]()

Production:

Certification:

![]()

![]()

![]()

-

Central loose tube cable,MM OM4,water blocking glass yarn,6.0mm for outdoor/indoor use

-

Outdoor Fiber Optic Cable GYTA Aluminum Polyethylene Laminate

-

GYFTY outdoor fiber optical cable with FRP strength member with armid yarn for

-

Loose tube stranding GYFTY outdoor fiber optic cable with FRP with armid yarn

-

CPRI LC to LC FTTA outdoor fiber optic patch cord duplex 7mm diameter for outdoor use

-

Underground Armored Outdoor Direct Buried Fiber Optic Cable GYTA53 reach to 288cores